A smaller fiber diameter results in dramatically better sound absorption. With a fiber diameter 3 to 30 times smaller than competitors, Sonozorb’s microfiber structure allows better performance across the frequency range with less trade-offs.

A smaller fiber diameter results in dramatically better sound absorption. With a fiber diameter 3 to 30 times smaller than competitors, Sonozorb’s microfiber structure allows better performance across the frequency range with less trade-offs.

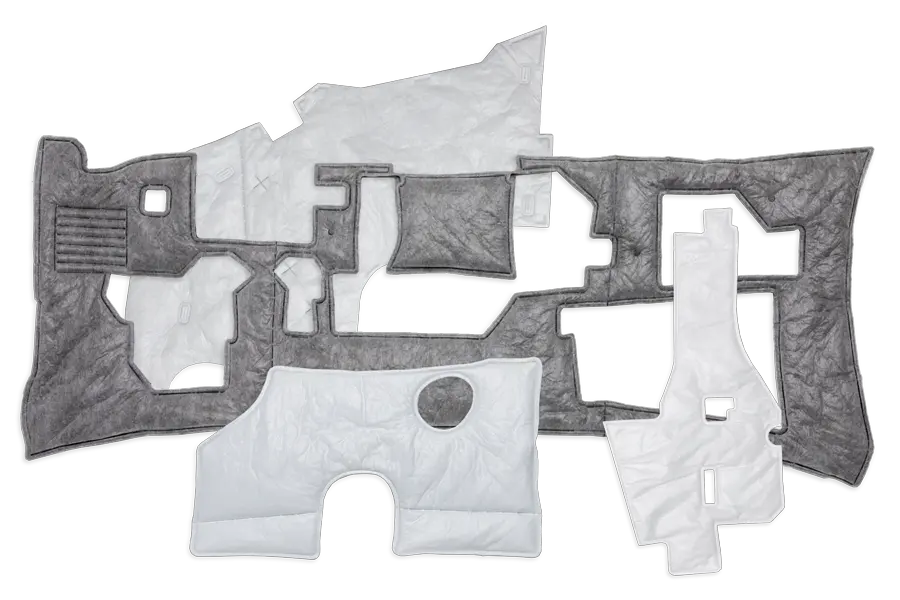

More than just raw material, Sonozorb is fabricated and finished to your specifications. Not only does this streamline your supply chain, it ensures product integrity and performance that can otherwise be compromised by third-party converters. Utilizing industry leading techniques, we carefully maintain loft throughout the manufacturing process.

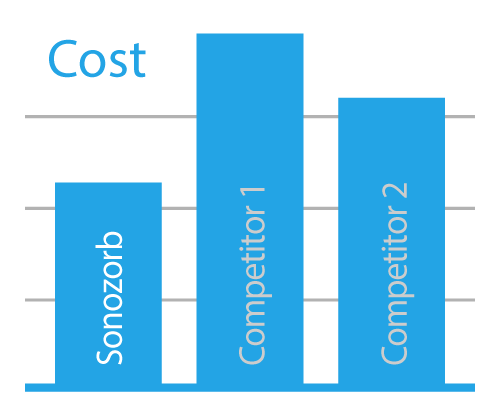

Combining exceptional technology with efficient manufacturing, Sonozorb provides you with the best cost-to-benefit ratio of any synthetic acoustic insulation available – with costs often similar to inferior cotton shoddy.

With today’s demanding applications, weight is more important than ever. Sonozorb delivers exceptional performance in a lightweight package.

Sonozorb can be locally compressed to eliminate potential design interference. Ultimately, the results are a three-dimensional design at a two-dimensional process cost.

Sonozorb is hydrophobic and will not absorb or hold water. The interspatial nature of the product allows ventilation to avoid trapping moisture.

Because Sonozorb is 100% polypropylene, waste material can be repelletized for use in other applications – making Sonozorb an extremely earth-friendly product.

The blanket of micro-fibers is fused together, then encapsulated with a spunbond scrim on both sides for added strength and fiber protection that will not settle in vertical applications.

The easy to handle, dust free blankets support a clean and safe manufacturing environment.